SDMO Kitting

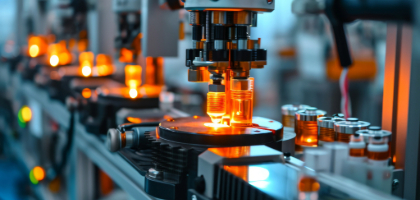

Promote Efficiency and Streamline Processes in Kitting.

Sage Distribution and Manufacturing Operations (SDMO) removes complexity and improves visibility into not just inventory, but all aspects of your business. Having real-time data on your inventory levels and reorder points gives your business a competitive advantage.

When designing and maintaining item records, users can establish bills of materials (kits) and routings. Cost savings and margin gains will come naturally with component costing on the bill of material level. Routings plus labor reporting can help improve efficiencies on the production floor.

When designing and maintaining item records, users can establish bills of materials (kits) and routings. Cost savings and margin gains will come naturally with component costing on the bill of material level. Routings plus labor reporting can help improve efficiencies on the production floor.

Kits are created to fulfill both make-to-order and make-to-stock items. Material and or labor can be tracked on kits depending on what your business needs are. Users can enter completions on the fly for finished goods, keeping inventory updated in real time.

Scheduling has never been easier than with SDMO’s calendar view with drag-and-drop capabilities. Seeing the overall workload by day, week, or month for a specific department allows production staff to easily see capacity levels. When a kit needs to be rescheduled, it’s as simple as dragging and dropping it to the appropriate day. The calendar can be displayed on a digital dashboard for all production staff and to replace your current whiteboard.

All daily tasks will be modernized with simplified workflows and rapid data-entry screens in sales order entry and purchasing. As transactions are entered, reports are updated in real-time allowing for operational visibility and swift decision-making abilities.

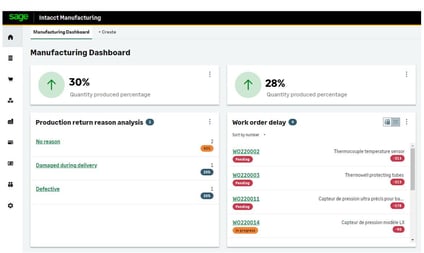

Track and Analyze Production Variances

In the SDMO software, the Planned versus Actual analysis compares planned costs of an item against the actual cost. The planned costs come from the item's bill of material and routing whereas the actual costs are calculated from production employee's time and material entry. These actual costs are tracked real-time ensuring that the analysis report is always up to date and allows management to monitor performance and efficiencies.

Get More Out the Door Faster

With improved efficiencies on your production floor and a reduction in inventory stock-outs, your business will be able to get finished goods out the door faster than ever before. The shipping process can be streamlined or even automated, allowing for more time to be spent focusing on data and growing the business.

Workorder Types Right for Your Industry

There are three different categories and two different types (or statuses) of work orders you can create. This promotes the flexibility of the software. The category of workorder depends on if you need to track time and materials, just time, or just materials. The status of the workorder focuses on if you're tracking progress against the order or not.

Purpose-Built for Kitting Businesses

- Data is displayed on user-friendly dashboards and reports that have drill-down capabilities

- Explode bill of materials within kits to see all associated sub-assemblies

- Use note fields within vendor and customer transactions to collaborate internally

- Room to expand your business with multi-location, multi-currency, multi-lingual functionality

.png?width=220&height=66&name=DiamondPartner__Color_RGB%20(2).png)