Sage Fixed Assets

Monitor and Control Fixed Assets Throughout the Life Cycle

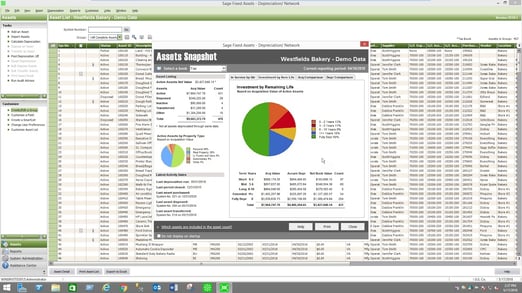

The many detailed administrative tasks required to manage fixed assets effectively can overwhelm an organization of any size. Thanks to an intuitive use interface, Sage Fixed Assets: Depreciation gives you the flexibility to manage the entire fixed asset life-cycle, from acquisition to transfer and disposal.

With advanced fixed asset accounting and reporting features, Sage Fixed Assets: Depreciation can help you prepare your year-end financials, allocate costs, calculate depreciation, eliminate redundant data entry, and store digital images of key asset records such as purchase orders, warranty information, and

insurance records.

Gives you the flexibility to manage the entire fixed-asset lifecycle for both profit businesses and nonprofit organizations, as well as prepare your year-end financial statements and tax returns, allocate costs, calculate depreciation, eliminate redundant data entry, and store digital images of key asset records.

With automated inventory functionality and built-in reconciliation capabilities, Sage Fixed Assets—Tracking makes keeping track of the fixed assets you use to run your organizations a whole lot easier.

Take control of your fixed assets before they even become fixed assets with flexible management of capital budgeting and construction-in-progress projects.

Create an endless variety of custom reports, including charts, graphs, and advanced formatting options.

Get up and running quickly with customized inventory and professional services as well as expert hands-on training.

Which Business Care Plan is Right for You?

Pick your version and plan ... VBCC can reduce your asset management workload.

Custom integration with your ERP System | No more manual data entry | Import new assets | Mass changes to existing assets | Custom reports | Remote software installations and updates

Gold |

Silver |

|

|

Software Version & Legislative |

X | X |

|

Unlimited Toll-Free Telephone & Live Chat Technical Support |

X | X |

|

24-Hour Online Access to Our Expert Knowledge-base |

X | X |

|

Sage Fixed Assets TechFlash E-Newsletter |

X | X |

|

Online Community Access |

X | X |

|

Sage Fixed Assets Anytime Learning Online Training |

Unlimited | 10% Discount |

|

Discount per Registration for Sage Summit Annual Customer Conference |

$200 off | $100 off |

|

Priority Access to Technical Assistance for the Sage Fixed Assets Customer Support Team |

X | |

|

First Call Access to Most Senior Support Analyst Available |

X | |

|

Annual System Check |

X | |

|

Sage Fixed Assets Classroom Training |

20% Discount |

- Sage Operations Management provides tools to quickly get accurate job cost estimates by determining the costs of the job’s components, including material, labor, and sub-contracted services. You get final pricing information and Sage Manufacturing software also allows you to quickly determine the total costs so you can make the best possible pricing decision.

Integration with Sage 100 Inventory Management helps you quickly tabulate material costs. Whether you use standard cost, LIFO, FIFO, average cost, lot valuation, or a combination of these valuation methods, Sage Operations Management will estimate your material cost using the current value of the materials needed. Items not kept in inventory that will need to be purchased direct to the job can also be estimated, without having to add the item to your inventory system. Labor is estimated by calculating the number of hours to be performed in a work center by your cost for that work center. Outside services are also estimated in as much detail as you wish to provide.

Key Features:

- Reuse past quotes by copying from existing templates to speed up the creation of new estimates.

- Combine bills of material, routers, labor, and contracted services to create a detailed cost roll-up.

- Easily select options and calculate pricing with Sage Operations Management add on, Product Configurator.

- Dynamically update material costs to reflect recent purchases.

- Calculate a suggested price using the desired markup using margin or profit for the calculation.

Sage Operations Management integration with Sales Order lets you streamline workflow so that all job information is available from a single source. With Sage Operations Management and Sage 100, entering orders is simplified because the sales order and work ticket function are linked and generated in the same order entry step.

Sales Orders - Sales orders are entered using the Sales Order Module of Sage 100. Sage Operations Management integrates this function with the creation of work tickets that are created directly from the sales order line. What does this mean? Let’s say your customer wants to order a red wagon and you need to make this wagon. If you gave your customer a quote for the wagon both the sales order and the work ticket are created by merely pulling up the quote and clicking on convert to order.

Work Tickets - Creating a work ticket to fulfill a sales order is also done for you by Sage Operations Management through its comprehensive work ticket management software features. In the example above, if the red wagon was not previously quoted, entering the line item for red wagon in the sales order can automatically create the work ticket to make the wagon by using the template associated with the red wagon Sage Operations Management job shop and tracking software will auto-generate the work tickets whenever demand and allocations for the stock item will bring inventories down to your minimum stock level.

Key Features:

- Quickly convert from an approved detailed quote to a sales order

- Generate work ticket orders automatically

- Check material availability before release

- Product Configurator can easily create Sales Orders and Work Ticket

- Attach product documentation and procedures specific to the job

Job Planning is a key part of your production process including key milestones such as creating the quote, entering the sales order, verifying the accuracy of the router, the bill of materials, material availability, notifying purchasing of shortages, checking production schedules for resource availability, and more. Typical manufacturing capacity planning software handles production well but often lacks an efficient communication system between work groups and departments. With Sage 100 Operations Management job shop tracking software and the Sage 100 Business Alerts Module, communications between your different work groups can be automated.

Sage Operations Management tracks status changes to the work tickets. When a status change is detected by the Business Alerts module, it automatically sends an e-mail to the next person in line responsible for the job. In other words, as soon as the sales order is entered, Production Control is immediately notified that they can begin checking the order before the job is released for work.

In addition, Sage 100 Operations Management also allows you to track the impact on job costs that result from necessary Production Control changes. The estimated job costs from materials, labor, and services that were entered either as a quote or a sales order can be tracked against the revisions made by production control. When work on the job begins, the actual costs are tracked separately from the original estimates and the revised estimates.

Key Features:

- Proactively monitor the status of your jobs, delivering the tools to review, refine, and improve estimating and job planning

- Verification of quote accuracy before production starts

- Determine material availability

- Notify purchasing of shortages

- Check production schedules

- Easily track original versus revised estimates

Sage Operations Management graphical scheduling tools help you prioritize your job schedules and allow you to meet promise dates. The Sage 100c Manufacturing scheduling board alerts you to overloaded resources that could jeopardize the schedule and also provides tools allowing you to correct the problems. These tools are used in a “what if?" mode so that before committing to the new schedule, you can verify that fixing one problem did not create a new problem elsewhere.

Key Features:

- Graphical real-time scheduling lets you see bottlenecks and delays and take quick, decisive action

- Easily identify what you are capable of promising

- Graphical scheduling tools lets you view scheduled jobs as a Gantt chart or bar graph against resources

- “What-if" and drag ‘n drop scheduling and analysis tools

- Change resources available “on the fly"

- Capable to promise calculation helps keep jobs on schedule so there aren’t missed delivery dates

- Visual warnings alert you to capacity and material constraints

- Management by exception tools

- Integrated MRP/ERP system streamlines workload

The Sage Operations Management Time Tracker module lets your workers report on what they have completed, and the materials they have used, in real-time. Using terminals out on the shop floor, bar coding, or web-based reporting, employees can directly enter their time and materials for the jobs they are working on.

With Sage Operations Managements Time Tracker you are kept up to date on the status of all of your jobs and can respond to customer inquiries about their jobs promptly.

The actual cost of the employees’ time (including overtime) and the cost of the materials is immediately available for management analysis. The status of a job is available while the job is still being worked on, meaning that cost overruns are visible when you can still react and make changes. Also, exception reporting lets you know when a job is not running as scheduled. When inventory is issued to a job, it is charged immediately to the job, and the on-hand quantity of that inventory is also updated. Knowing the actual available inventory quantities allows you to make better purchasing decisions and make sure that inventory will be available for the next job that requires the same material.

Since Sage Operations Management and Sage 100 are tightly integrated, your accounting department gets the benefit of running labor and inventory ledgers so that verification can be made before posting to the journals. Accounting maintains its controls and procedures while Operations still gets real-time reporting on the status of their jobs.

Key Features:

- Real-time management tools to manage your job costs effectively

- Integrated job cost accounting and job management

- Real-time job status and reports

- Real-time actual versus estimated costing

- Projected costing based on work completed

- Real-time alerts letting you know of potential cost overruns while in production

WI Office Locations: Brookfield, Kenosha and Madison

IL Office Location: Chicago

Phone: 262-797-0400

Email: info@v-bcc.com